Leveraging its extensive expertise in electroplating technique, FUKUDA is involved in researching and developing copper and various other new metal foil products.

Developing Copper Foils for Next-Generation High-Speed Communications

High-Speed Communication and Copper Foils

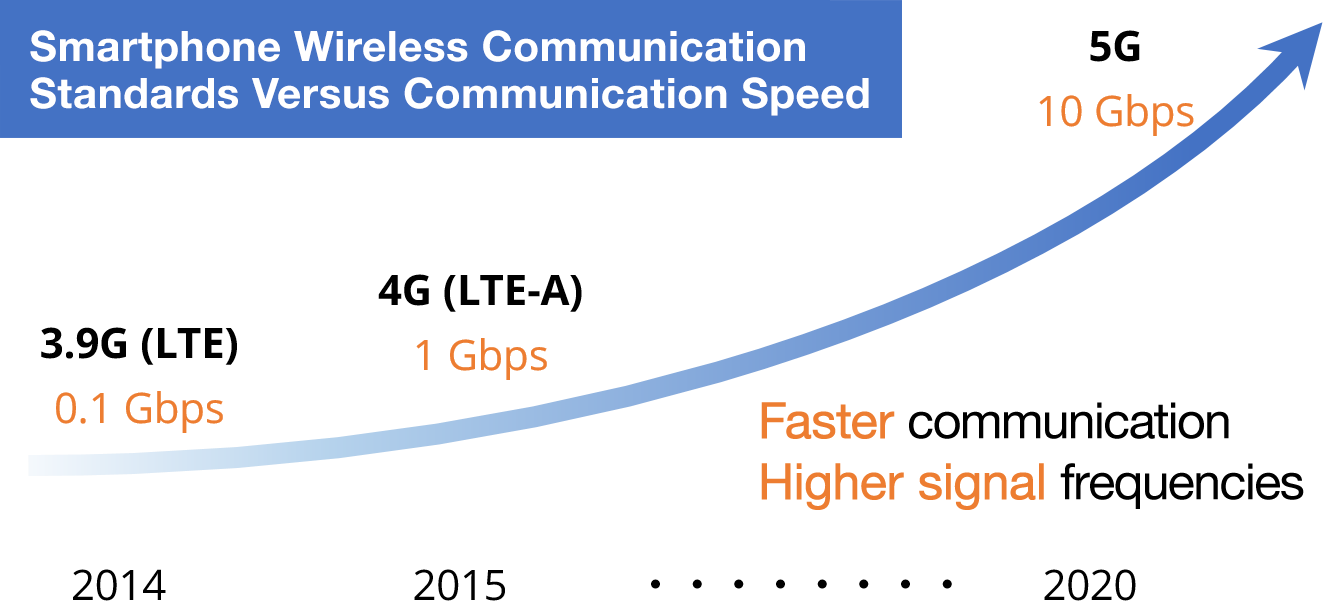

Computers, smartphones, televisions, and other electronic devices send and receive large amounts of data as electrical signals. The speed of such communications has been increasing each year, with electrical signals being transmitted at increasingly high frequencies. With next-generation 5G standards scheduled for 2020, the frequency band used for smartphones and other mobile communication devices will reportedly increase from the current 4G band, that extends from a few hundred MHz to a few GHz, to a 5G band that extends from 10 to 20 GHz or more.

Copper foil is used in printed circuit boards, which are installed in all sorts of electronic devices. The foil serves as the wiring used to send and receive electrical signals. This development work is to create a copper foil that is ideal for such next-generation high-speed communication applications.

Why Are New Copper Foils Needed?

As mentioned above, copper foil is used as electrical wiring, but signal intensity decreases (attenuates) as the signal travels through the wires. This attenuation is referred to as transmission loss. The higher the electrical signal frequency, the higher transmission loss.

Transmission losses can be explained in terms of a phenomenon called the "skin effect," where the higher the frequency of an electrical signal, the more the current flow is concentrated at the surface (skin) of a conductor. Given a typical copper foil about 6 to 70 µm thick and a 10 MHz signal frequency, for example, the skin effect results in most of the current traveling through the 20 µm range closest to the surface. However, for a 10 GHz signal frequency, that range is an extremely narrow 0.7 µm or so from the surface. This example illustrates how copper foil skin effects increase as the frequency increases.

Transmission losses are affected by the surface profile and various other factors. For example, surface bumps can lengthen the effective current flow path, which can cause additional attenuation of signal intensity, or in other words, increase transmission losses. Previous copper foils were never designed from that perspective. Therefore, new copper foils need to be developed that can support the increasingly high transmission speeds of electronic devices.

Developing Copper Foils

The figure on the right shows the transmission loss levels of the copper foil currently being developed for next-generation high-speed communication compared to conventional copper foil. It shows that the copper foil for next-generation high-speed communication can transmit higher frequencies without increasing the transmission loss levels or, alternatively, it can significantly decrease the transmission losses given the same frequency level. From the microstructure to the surface treatment, FUKUDA is making further improvements and advancements to our extensive accumulation of electroplating technology and conducting research and development to create a completely new copper foil that is optimized for next-generation high-speed communication.

FUKUDA is committed to pursuing additional improvements to transmission loss characteristics in the future and to pioneering high-speed communications from the perspective of materials.

Inquiries and requests for small samples are welcome.