FUKUDA has developed a metal powder for use in cold spray deposition.

Powders for Cold Spray Deposition

Cold Spray Deposition Method

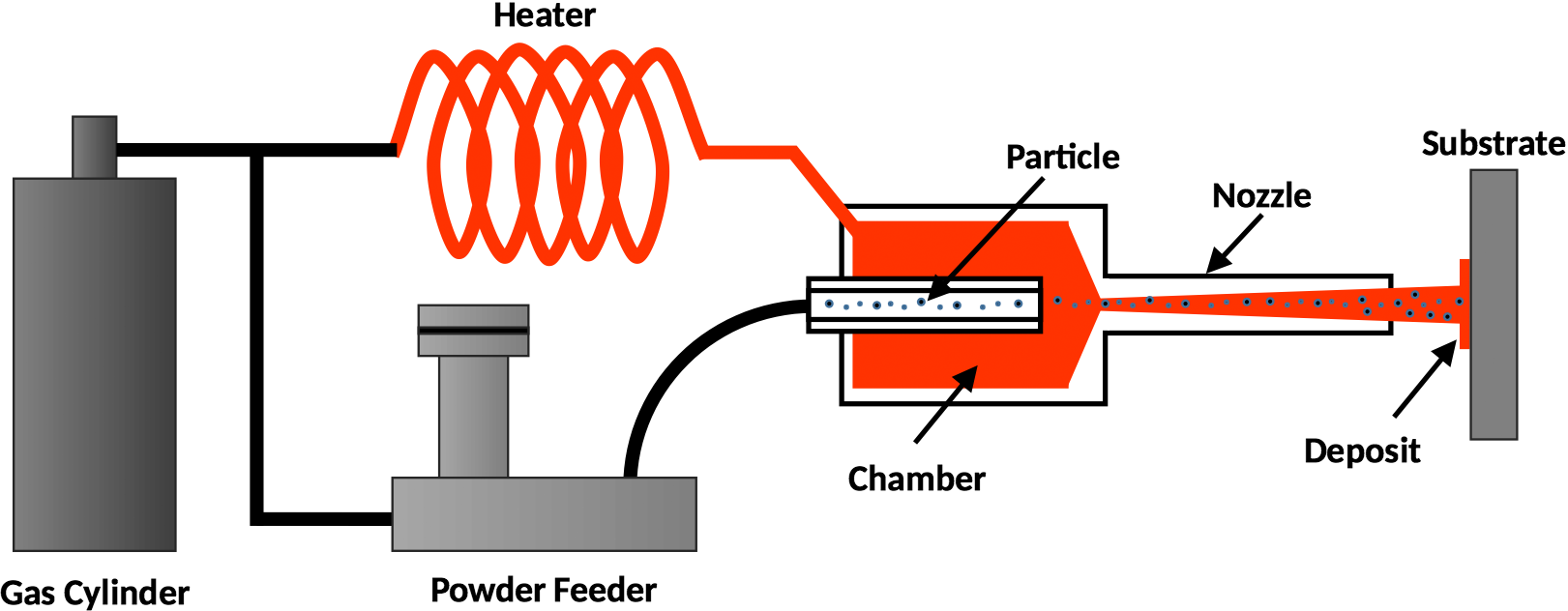

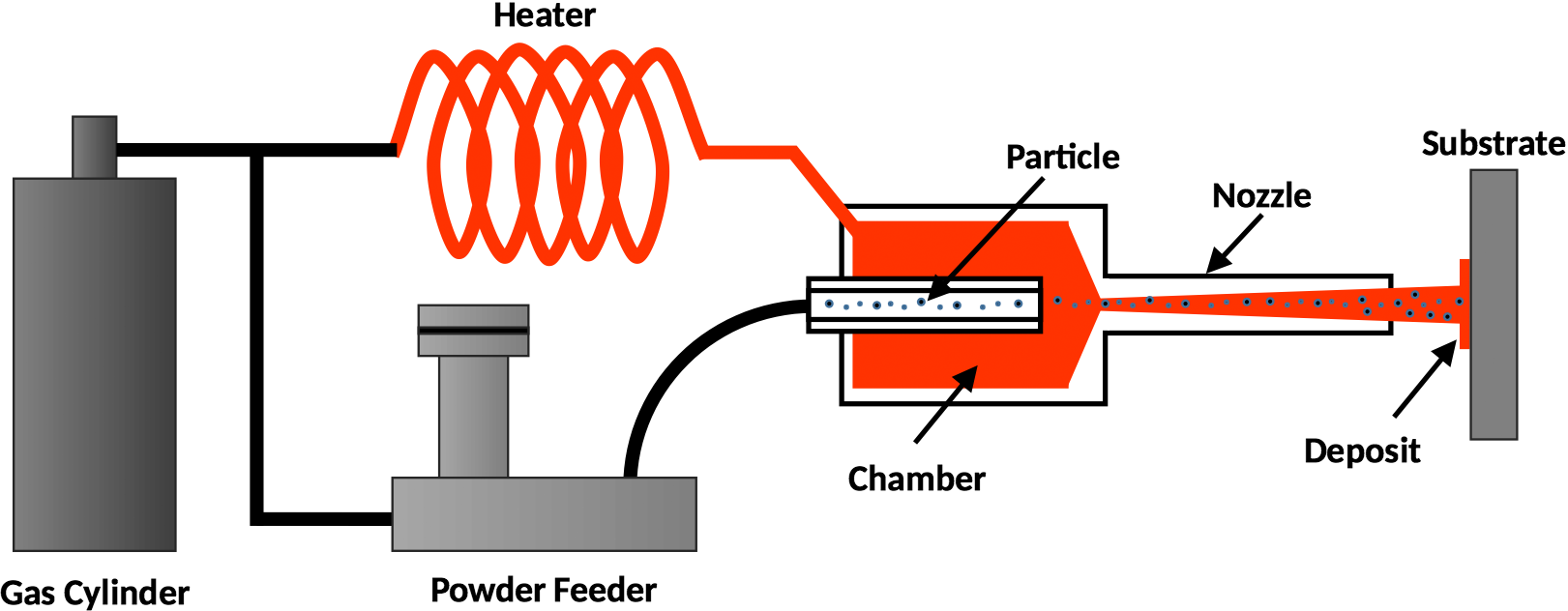

Cold spraying is a coating deposition method that uses supersonic gas flow to bombard the surface being coated with solid powder particles. Cold spraying technology is similar to thermal spraying in terms of depositing a coating of particles by impacting them onto a surface, but cold spraying uses lower processing temperatures than other thermal spraying methods, which helps reduce coating oxidation and lower thermal effects on the substrate. It also offers the following advantages.

- High deposition efficiency

- Extremely dense coating

- Reduction of thermal stresses

- Thick coatings can be formed

Diagram of Cold Spray System

Example Using Cold Spray Technology

Aluminum-Copper Composite Flange

Source: Plasma Giken Co., Ltd.

Due to its various advantages, cold spraying not only offers an alternative surface modification technology to conventional thermal spraying, but it is also being considered for use on copper flanges, sputtering targets, superconducting motors, gas turbines, batteries, and a wide variety of other applications. However, because this is a relatively new technology, many of the powder material properties required for such an applications are still not well understood, and it is essential to develop new powder materials with properties suitable for cold spraying.

Developing Powders

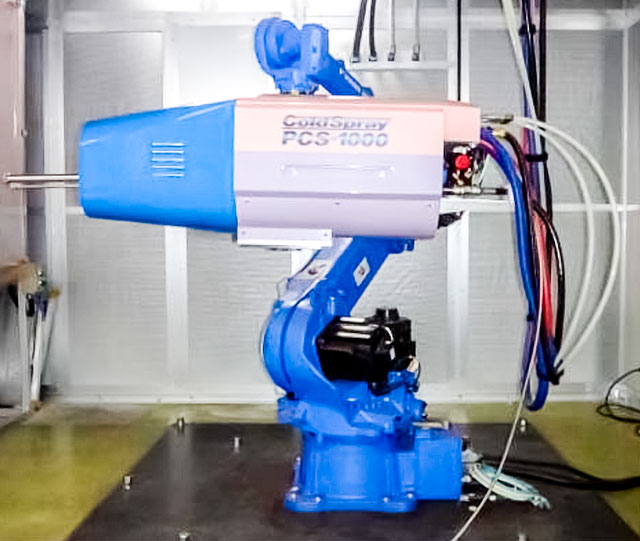

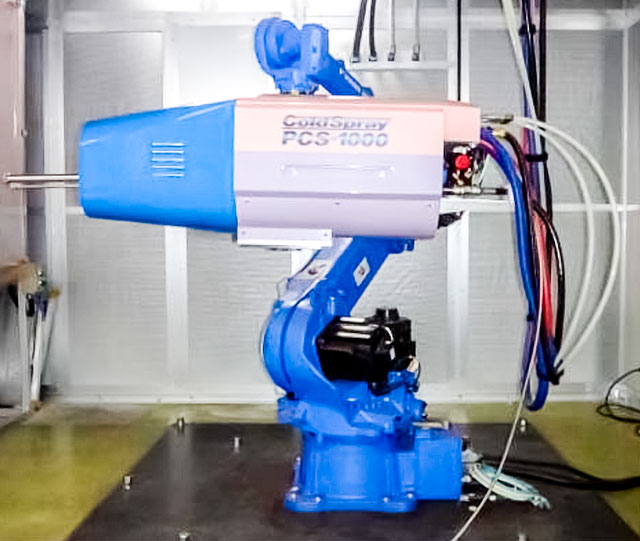

PCS-1000 Cold Spray Equipment

(made by Plasma Giken Co., Ltd.)

Max. gas pressure: 5 MPa

Max. gas temperature: 1000 ˚C

Optimal material properties exist for each thermal spraying method, not just for cold spraying. Therefore, FUKUDA has installed high-pressure cold spray equipment (PCS-1000) for use in researching and developing powders for anticipated cold spraying applications. FUKUDA also offers prototyping and coating evaluation services.

Publications Related to Cold Spraying

| 2022 |

- Comparison of CuCrZr Build by Cold Spray and Powder Bed Fusion ( 116th Japan Thermal Spray Society Autumn Meeting )

- Evaluation of cold-spray coating using CuCrZr powder with different morphology ( 115th Japan Thermal Spray Society Spring Meeting: On-demand video distribution )

- Comparison of Cu fabricated by cold spray and additive manufacturing ( 115th Japan Thermal Spray Society Spring Meeting: On-demand video distribution )

|

| 2018 |

- Influence of the Particle Shape and the Heat Treatment to Adhesion Strength in Cold Spray ( Thermal Spraying Technique Vol.37, No.3, pp. 61-68 )

|

| 2017 |

- Feasibility Study of High-Strength Brass Coatings by Cold Spray Process ( Japan Society of Powder and Powder Metallurgy )

- Influence of the Particle Shape and the Heat Treatment to Adhesion Strength in Cold Spray ( 105th Japan Thermal Spray Society Fall Meeting )

- Evaluation of High-Strength Brass Coatings Fabricated by Cold Spray Method ( Spring Meeting of Japan Society of Powder and Powder Metallurgy, 2017 )

- Report on the Research of Cold Spray in Fukuda Metal Foil & Powder Co., Ltd. ( Japan Thermal Spray Society / Cold Spray Reserch Meeting )

|

| 2016 |

- Prediction of Locations of Poor Splat Bonding in Multi-Traverse Cold Spray Deposition ( Journal of the Japan Society of Powder and Powder Metallurgy Vol. 63, No. 7, pp. 504-510 )

- Influence of the Particle Shape to Adhesion Strength in Cold Spray ( 103rd Japan Thermal Spray Society Spring Meeting )

- Study of Copper and Copper Alloy Powder Coating Deposition by Cold Spray Method ( Japan Society of Powder and Powder Metallurgy, Powder Manufacturing Subcommittee )

|

| 2015 |

- Prediction of Locations of Poor Splat Bonding in Multi-Traverse Cold Spray Deposition ( APMA2015 )

- Evaluation of high-strength brass coatings fabricated by cold spray ( APMA2015 )

- Relationship Between Heat Treated Ni-Cr Alloy Powder Properties and Cold Spray Coating Properties ( 101st Japan Thermal Spray Society Spring Meeting )

- Cold Spray Properties of Ni-Cr Alloy - Influence of the Particle Shape and Amount of Added Chromium ( Thermal Spraying Technique Vol. 34, No. 4, pp. 26-30 )

- Investigation about Applying STAC-method to Cold Spray ( Journal of Japan Thermal Spraying Society Vol. 52, No. 2, pp. 80-83 )

|

| 2014 |

- Evaluation of Cold Spray Coating by Ultrasonic Washing ( Journal of Japan Thermal Spraying Society Vol. 51, No. 4, pp. 126-128 )

- Study of Coating Deposition Simulation in Cold Spray Coating ( 100th Japan Thermal Spray Society Fall Meeting )

- Evaluation of Cold Spray Coating by Ultrasonic Washing ( 99th Japan Thermal Spray Society Spring Meeting )

- Influence of the Amount of Chromium Added in Nickel Alloy in Cold Spray ( 99th Japan Thermal Spray Society Spring Meeting )

|

| 2013 |

- Relationship Between Heat Treated Copper Particle Properties and Cold Spray Coating Properties ( 98th Japan Thermal Spray Society Fall Meeting )

- Study of Copper Powder Manufacturing Methods Suitable for Cold Spraying ( Thermal Spraying Technique Vol. 33, No. 2, pp. 77-81 )

- Relationship Between Copper Particle Properties and Adhesion Rate for Cold Spraying ( 97th Japan Thermal Spray Society Spring Meeting )

|

Inquiries and requests for small samples are welcome.